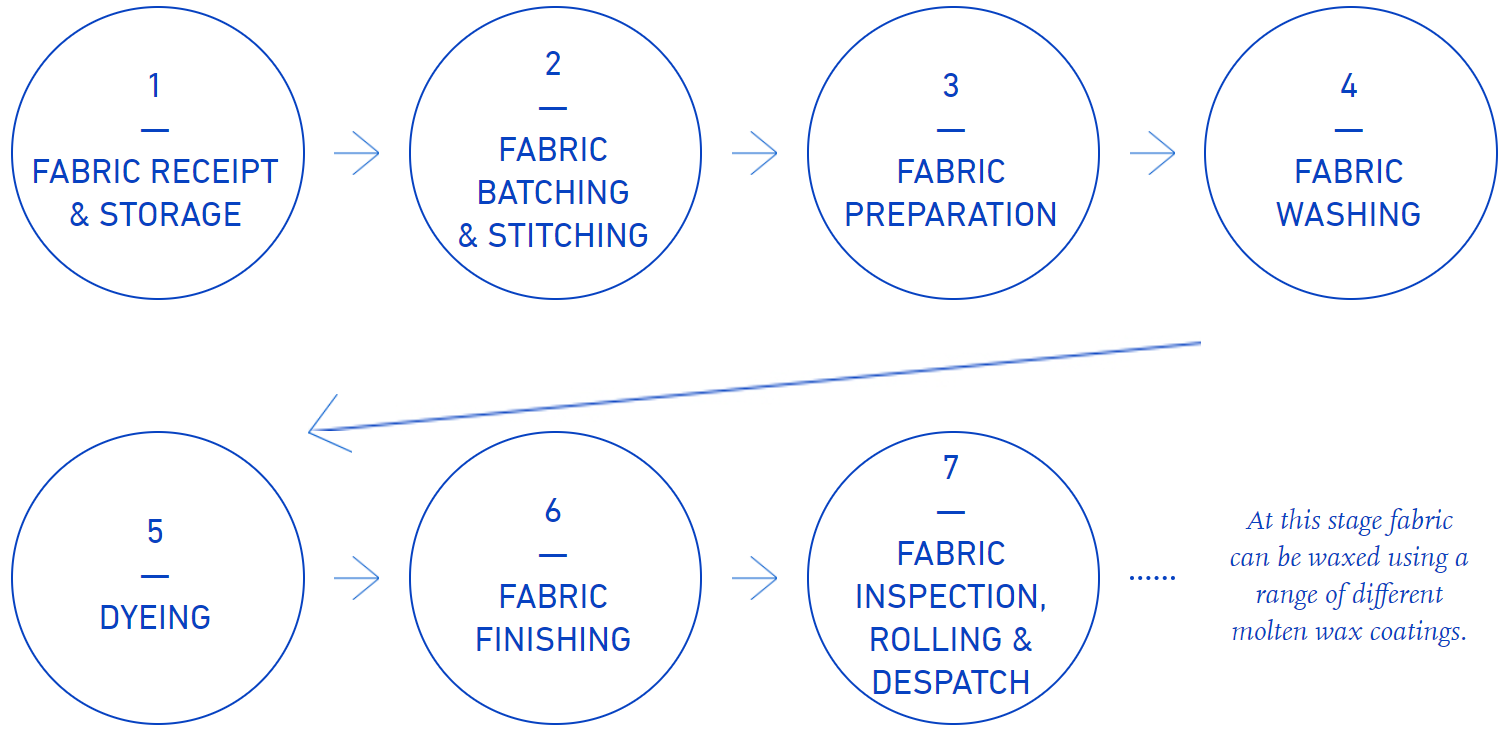

OUR PROCESSES

Process Stages

Dinsmore’s current fabric processing facilities, within our 2 factories in Kells and Meltham, contain a wide range of options in terms of blends of fabrics, treatments and widths. Distinct process routings are defined for each product/order to achieve the requirements of each customer and order. Our process stages are outlined below.